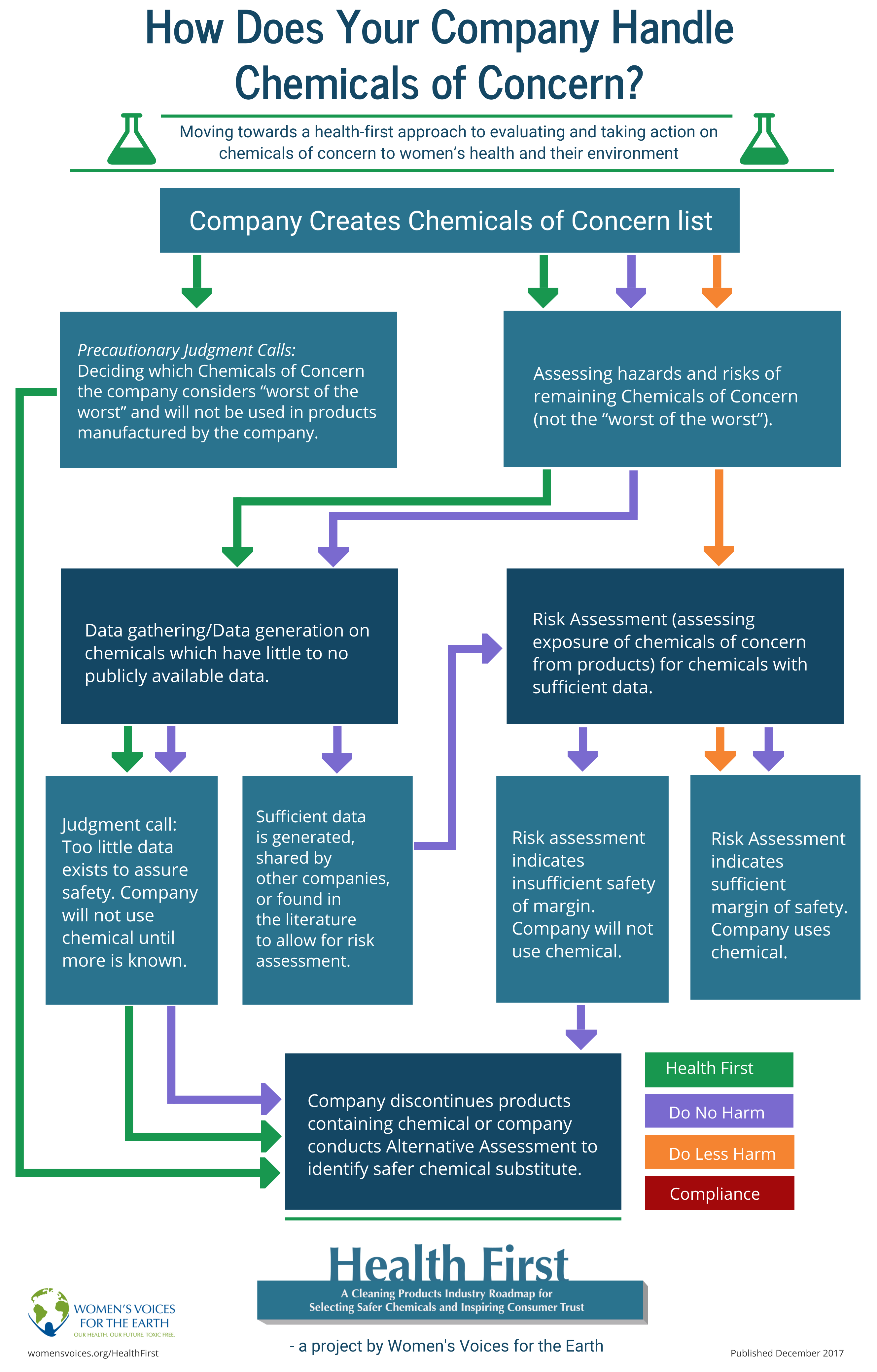

Why a Health First Roadmap?

Currently, no company in the cleaning products sector is fully transparent about how it manages chemicals and ensures that it is using safe ingredients. This is both a serious problem for public health and for companies that are committed to building consumer trust. Read more.